Demystifying manufacturing in Shenzhen: lessons learned

- Vela Georgiev

- May 1, 2021

- 4 min read

Updated: Feb 20, 2023

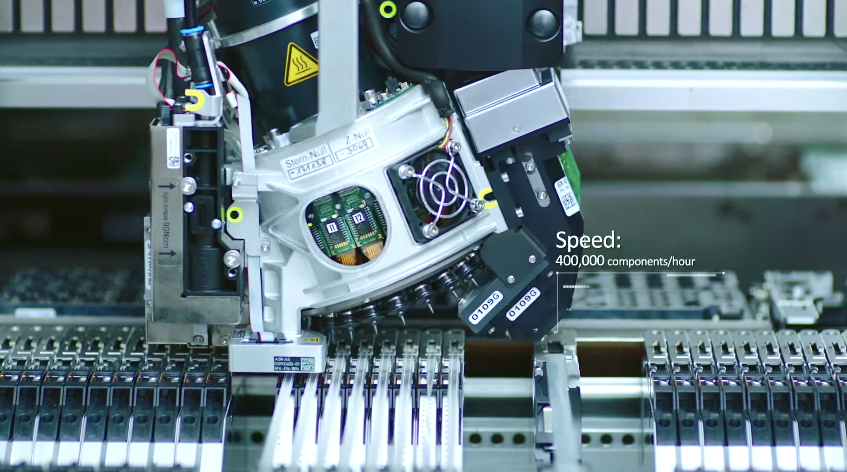

Known as the ‘world’s factory,’ Shenzhen city is the global epicentre of electronics. While there’s unrelenting demand for gadgets globally––most people don’t actually know the complex processes used in order to produce them.

In 2017 a HardworX tour of Shenzhen was life-changing for a group of engineers, entrepreneurs, and startup founders. The aim of the tour: to demystify hardware manufacturing in China. It did just that. Post-tour the participants felt confident in engaging manufacturers world-over to produce their own products.

The tour highlighted the importance of exploring factories and building strong relationships. In China it’s doable: there’s a factory to produce anything the entrepreneur is willing to create. Not-just-that, once an understanding of factories is learned, that knowledge is valuable for manufacturing across the globe.

Anything is possible

China is famed globally for producing all kinds of products. Check the label of any piece of furniture, electronic, or piece of clothing and the chance is relatively high: it’ll be made in China. The country produces almost everything. That includes electronics, mechanical products, machinery, plastic products, iron, furniture, auto parts, steel products, and so much more.

For many, however, a perception exists that in China, only some things are possible. While Chinese manufacturers can produce many goods, they’re not known for design, nor necessarily known for very high-quality manufacturing.

The tour group soon found, however, this is a misconception. In China, anything is possible. Touring Shenzhen's factories and spaces, means breaking down perceptions entirely. Not only does China produce exceptional-quality goods––they produce goods at any scale from a minimum order of one, through to productions into the millions.

‘The trip opened up many doors and showed if you want to have something manufactured: it really is achievable,’ said Jonathan Oxer.

An ideal factory exists for almost every type of product, regardless of how niche it is, or whether it has been created before. In fact, the scale, variety, and possibilities in China are mind-blowing––an eye-opening thought for makers, engineers, and entrepreneurs alike.

Visiting Shenzhen

For tour participants, one of the key learnings of the tour was: the value of visiting Shenzhen in person. While this may not be possible for everyone, (and dependent on travel restrictions) hours of website research, regardless of how detailed, cannot replicate an in-person visit.

Finding the right factory, for the right product, is a journey; one that deserves time and effort. In order to produce the right products, at scale, finding the ‘perfect fit’ factory is an essential step in the process. Without an in-person visit, you may discover, down the track, that the factory is outsourcing aspects of production, or that there was an early miscommunication and that the product isn’t as expected.

Factory visits are also essential for networking, connecting, and pitching oneself to find the perfect factory. In China, production is a two-way relationship. Relationship building is important. Continuing to nurture those relationships throughout production can be the difference between a successful production run and one with issues and miscommunications.

To go a step further, as in the case of LIFX, having someone on the ground means being able to control quality, solve any issues that arise, and continue to tweak the production. At LIFX, John Bosua spends much of his time in Shenzhen ensuring quality is high, the process is streamlined, and that he continues to nurture strong relationships in China.

Transferable skills

While China is arguably the world’s most important manufacturer of goods: it isn’t the only country worth considering. Participants made the exciting discovery that the skills learned on their Shenzhen tour, were immediately transferable to factories the world over.

Once a person has the opportunity to visit a scale of factories from high to low end, they’re able to develop an awareness and understanding of manufacturing principles. These skills include an understanding of supply due diligence, design for manufacture, early-stage through to final-stage testing, compliance, production quality, and failure modes.

One participant visited a Melbourne-based factory. During this visit, thanks to the Shenzhen experience, the participant knew what questions to ask, what to look for, and how to go about building a strong relationship. That confidence would likely never have been possible without in-depth factory tours.

Since factories operate similarly regardless of location, a visit to China isn’t the only way to discover and demystify manufacturing. But visiting, regardless of where is essential. Once an understanding of factories, and how they operate, is solidified: the skills are readily transferable.

The 2017 HardworX tour of Shenzhen helped to demystify hardware manufacturing, not just in China, but across the world. By engaging in person, focussing on building solid relationships, and understanding that anything is possible: doors can open. With perseverance, and the willingness to learn, producing the ‘next big thing’ really is possible. For startups and entrepreneurs, it’s an exciting prospect.

To learn more about the tour of Shenzhen and participants' learnings watch the documentary wrap-up below.

HardworX would like to thank all those who made the tour possible, and in particular:

Karl von Möller for his passion and dedication in producing this documentary series. The entire documentary episode list can be viewed here.

All of the factories for welcoming the tour group, spending time, and sharing knowledge. To view a list of the factories visited, click here.

The HardworX Shenzhen Innovation 2017 tour group consisted of tour leader Vela Georgiev, participants Andy Gelme, Brian Gilbert, Jon Oxer, Kemal Ajay, Liam Brennan, Noor Magesh, Sarah Last, Tom Partridge, Simon Holmes a Court, Hans Chang, and Karl von Möller.

Comments